Vancouver metal fabrication company JFC Steel Ltd., explains the process of working with a client to plan and fabricate their metal project or structures ideas.

Metal fabrication in Vancouver is commonly referred to as the process of constructing machines, metal products or structures from raw materials according to the design specifications and assembling various parts in shop or on site to deliver the final product to buyers or clients. It involves a set of value added processes since they add additional value to your metal product at each stage of the fabrication, and brings your design idea to life.

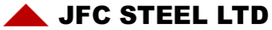

For any metal fabrication work to be done, the client who may be a builder, renovation contractor, equipment manufacturer, or reseller, has to develop a set of detailed drawings of the product and its various parts in the first place. These are known as shop drawings and include plans, elevations, sections and details of connections, anchorage and accessory items.

When the drawings are finalized, the client sends the drawings to the metal fabricator (also known as fab shop) with material specifications, and asks for a Request For Quotation. The clients may also consult with the in-house engineer to discuss the project in details. When the Vancouver metal fabricator bids for the custom fabrication processes along with relevant delivery or installation services, the client will confirm moving ahead with the work and the work order will be placed.

When the drawings are finalized, the client sends the drawings to the metal fabricator (also known as fab shop) with material specifications, and asks for a Request For Quotation. The clients may also consult with the in-house engineer to discuss the project in details. When the Vancouver metal fabricator bids for the custom fabrication processes along with relevant delivery or installation services, the client will confirm moving ahead with the work and the work order will be placed.

Once the order is placed, the metal fabricator begins to work on the project starting from the planning stage. This starts with ordering the appropriate materials according to design specifications. Sometimes, the fabrication company may come up with some suggestions about the material standards, when the client is not so sure about it other times the client will make specific requests. A comprehensive plan defining the essential processes involved is developed and it solely depends on the client’s needs and fabricator’s expertise. In most cases, metal fabricators are specialized in all relevant processes and services to get the project done with their own efforts and workmanship. In special cases, some of these processes may be sub-contracted out if needed based on the size, special requirements of the project.

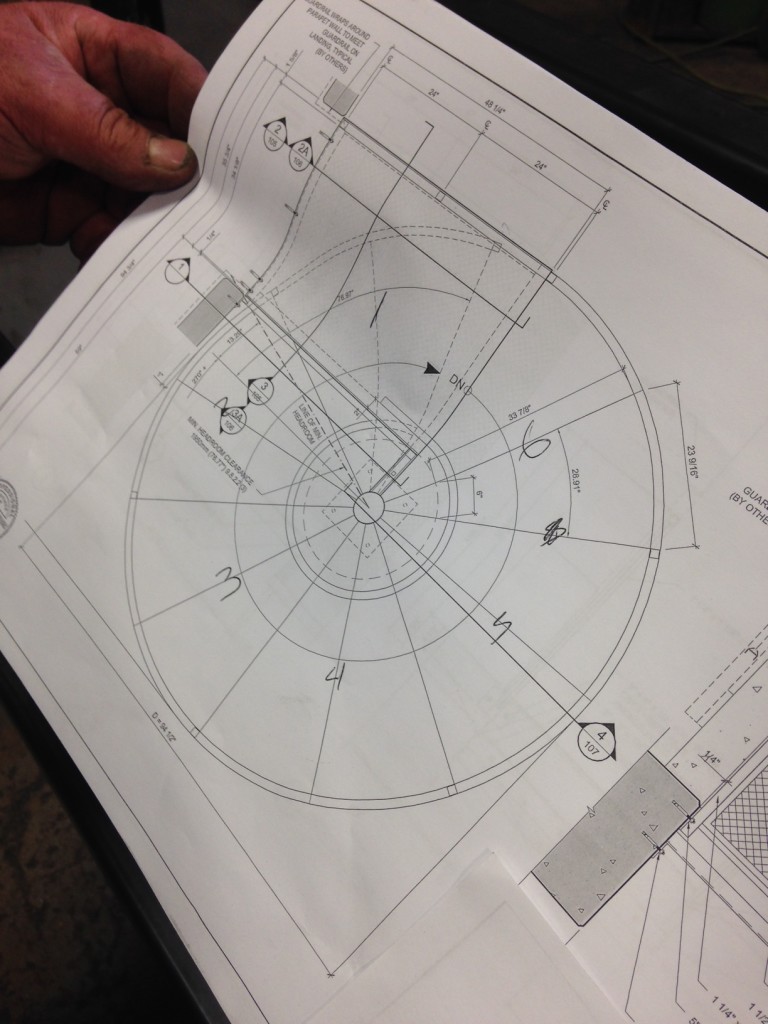

In the next phase, the build or removal process starts, and it works with cutting the materials to the correct sizes to form various parts of the product. Aviation snips, power-scissors, laser beams, mechanical saw blades or cutting torch are common tools used for cutting. Punching may also be needed to create holes of various geometric shapes including circles, rectangles and squares in the material and take out the scrap or slug. Stamping is very much similar to punching. The only difference is that there is no penetration involved and the dies simply creates a raised portion of the material without cutting.

In the metal deformation process, force is applied to change the geometrical shape of a piece of metal without removing any parts of it. The metal parts deform to achieve intended shape according to design specifications. Roll forming and spinning are similar process used for bending the metal parts. Deep drawing is another method that is particularly useful in case of ductile materials including brass, aluminum and copper.

When all parts of the metal product are ready according to the design, the finishing and assembly process begins. The metals parts are joined by bolting, welding or other fastening equipment. In most cases, the assembly is done in shop by setting the metal  fabrications accurately in position, alignment, and elevation with edges and surfaces level, plumb, true, and free of rack and measured from established lines and levels.

fabrications accurately in position, alignment, and elevation with edges and surfaces level, plumb, true, and free of rack and measured from established lines and levels.

When the project specific requirement says to install metal frames or structure on site, field welding is usually done to assemble all parts in proper position and alignment. In such case, adequate anchorage and fasteners are necessary for securing metal fabrications to in-place construction. When the entire installation is complete, cleaning and touch up painting is done to give a solid and brand-new look. The metal fabricator then delivers or hands over the project to the client and if everything goes well, the contract is terminated marking a successful completion of the project.

JFC Steel Ltd. is a North Vancouver metal fabrication company with vast experience in the commercial, industrial, residential and marine industries. If you have any questions or have a project in mind that requires the services of a Vancouver metal shop, please feel free to contact us.